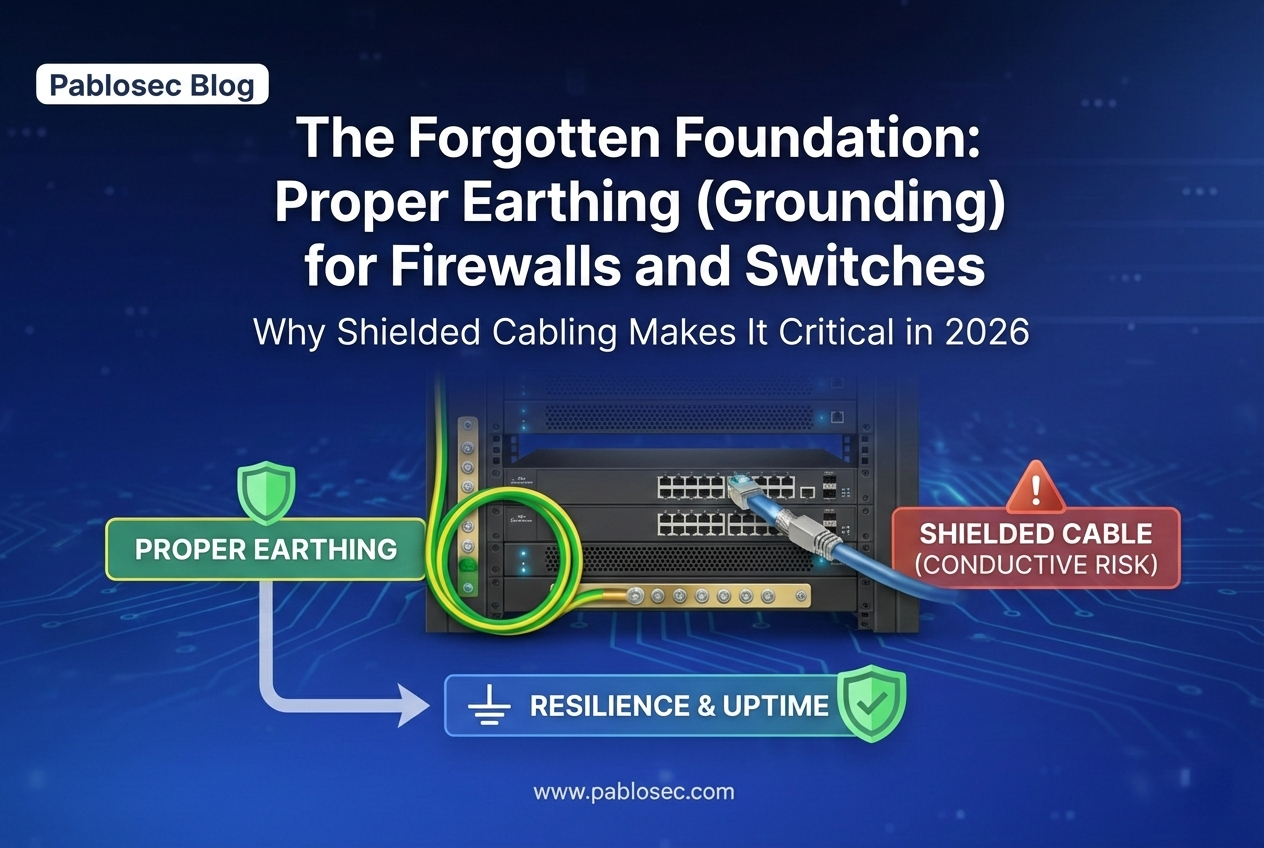

Why shielded Ethernet makes grounding more critical—and why relying on "rack rails" is a risk you shouldn't take.

When we design a new network, we obsess over the visible layer: throughput, redundancy, VLAN segmentation, and next-gen security policies.

But the most critical safety and reliability control is often the one we think about least: Proper Earthing.

In 2026, this is no longer just a "best practice" it is an operational necessity. As organizations aggressively adopt shielded cabling (FTP/S/FTP) to support high-power PoE and reduce noise for 10Gbps+ speeds, the electrical reality of your network has changed.

If you treat a shielded network the same way you treated an unshielded one, you aren't just risking noise—you are potentially turning your cabling into a conductive path for failure.

The Shift: Shielding Changes the Rules

In the past, Unshielded Twisted Pair (UTP) was the standard. It was mostly plastic and copper. Today, to combat interference and handle higher power loads, we use Shielded (FTP/SFTP) cabling.

Shielded cable is excellent for performance, but it introduces a new variable: Continuity.

That foil or braid wrapping your data pairs isn't just a barrier; it is a conductive metal pipe running through your building. It connects your endpoints, your patch panels, and your switches.

-

The Risk: If there is an electrical fault, a lightning strike nearby, or a "floating" voltage from a bad power supply, that energy needs to go somewhere.

-

The Reality: If you don't provide a clean path to earth, the energy will find its own path often through your expensive equipment rather than around it.

The "Rack-Only" Trap and the Blast Radius

A common response I hear is: "Don't worry, the rack is grounded."

Usually, that means there is a single green-and-yellow wire bolted to the bottom of the cabinet. While that meets basic safety code, it is often insufficient for sensitive electronics in a shielded environment.

Consider this scenario:

- You have a Core Switch at the top of the rack (40U high).

- The only earth point is at the bottom (1U).

- You have shielded cabling connecting the switch to a patch panel, then to a firewall.

If a surge or fault hits that switch, the current seeks the path of least resistance to ground. If the switch chassis isn't individually bonded, that current might travel through the shielded Ethernet ports, into the patch panel, down the rack rails (which are often painted and have high resistance), through the firewall chassis, and finally to the earth bar.

The Result: The fault current flows through your network ports to get to the ground.

This creates a "Blast Radius." Instead of one blown fuse, you lose a switch port, a firewall interface, and potentially the connected device.

The Solution: Reduce the Path to Earth

Engineering resilience is about physics. We want unwanted current to exit the system immediately, without traversing other devices.

1. Bond the Device, Not Just the Rack

For mission-critical hardware (Firewalls, Core Switches, OT Gateways), do not rely on the rack screws for grounding. Paint, oxidation, and loose cage nuts create high electrical resistance.

-

Best Practice: Use the dedicated grounding lug on the back of the device. Run a direct strap to the rack's vertical earth bar.

2. Treat the Shield as a Circuit

Shielded cabling must be terminated correctly. If you use shielded jacks, they must connect to a shielded patch panel, which must be bonded to the rack earth.

-

Warning: If you leave a shield "floating" (unconnected) at both ends, it becomes an antenna for interference. If you bond it poorly, it becomes a fuse.

3. Check Your Power

Grounding is a system. If your PDU (Power Distribution Unit) has a poor earth connection, your rack bonding has to work double-time. Ensure your electrical contractor tests the impedance of the circuit feeding the rack.

A Practical Checklist for Your Next Rollout

Before you sign off on a deployment, ask these four questions:

- Is there a vertical earth bar? Or just a single point at the bottom? Vertical bars allow short, direct connections for every device.

- Are the "Big Boxes" individually bonded? Your core firewall and switch should have their own strap.

- Is the paint scraped? If you are bonding to a painted rack rail, you need to scrape the paint to metal to ensure contact.

- Is the shielded path complete? Verify that the path from the endpoint > patch panel > rack earth is continuous.

Final Thought

You can have perfect firewall rules and redundant ISPs, but you cannot software-update your way out of a physics problem.

In 2026, the physical layer includes the electrical integrity of the shield. Grounding per rack is good. Grounding per device is what keeps you online.